Hydraulic Press Brake,Sheet Metal Press Brake

This AGL hydraulic brake’s pressure capacity is 135 tons, allowing it to process 3100mm long workpieces with a high processing accuracy and efficiency. We also ensure the structure and design was built to ensure the operating stability.

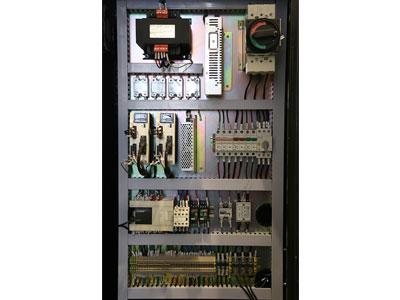

All components are sourced from Schneider, Mitsubishi, Panasonic and other internationally known brands, with a resolution power of up to 0.01mm. Input numbers on the operating panel and a servo drive back gauge finger ensure a fast response and accurate processing.

Machine Specification

| Type | 03512L | 1025L | 1030L | 12540L | 1330L | |

| Pressure Capacity | 350KN | 1000KN | 1000KN | 1250KN | 1300KN | |

| Bending Length | 1200mm | 2500mm | 3100mm | 4000mm | 3100mm | |

| Length of Stroke | 150mm | 150mm | 150mm | 150mm | 150mm | |

| Number of Oil Tank | 1 | 3 | 3 | 3 | 3 | |

| Maximun Pressure | 28.66Mpa | 33.8Mpa | 33.8Mpa | 30Mpa | 31Mpa | |

| Speed | Rise | 37-47mm/sec | 37-47mm/sec | 37-47mm/sec | 37-47mm/sec | 37-47mm/sec |

| Bend | 7.5-10mm/sec | 7.5-9.2mm/sec | 7.5-9.2mm/sec | 7.5-9.2mm/sec | 7.5-10mm/sec | |

| Descend | 47-66mm/sec | 47-66mm/sec | 47-66mm/sec | 47-66mm/sec | 47-66mm/sec | |

| Motor Power | 3kw | 7.5kw | 7.5kw | 7.5kw | 11kw | |

| Oil Tank Capacity | 27L | 50L | 72L | 65L | 70L | |

| Weight | 2250kg | 6000kg | 7100kg | 8800kg | 7400kg | |

| Outside Width of Frame | 1200 | 2500 | 3000 | 4000 | 3000 | |

| Inside Width of Frame | 1020 | 2000 | 2550 | 3000 | 2550 | |

| Throat Depth | 200 | 405 | 405 | 420 | 405 | |

| Distance between Upper and Lower Worktable | 300 | 300 | 300 | 300 | 300 | |

| Daylight Opening | 420 | 420 | 420 | 420 | 420 | |

| Height of Lower Worktable | 988 | 1058 | 1080 | 1081 | 1082 | |

| Total Height | 2175 | 2530 | 2530 | 2675 | 2670 | |

| Side Plate Height | 1880 | 2190 | 2190 | 2208 | 2206 | |

| Machine Width | 1410 | 2564 | 3340 | 4175 | 3340 | |

| Total Width | 2252 | 3800 | 4210 | 4700 | 4310 | |

| Total Depth | 1130 | 1555 | 1567 | 1607 | 1607 | |

| Inquiry | Inquiry | Inquiry | Inquiry | Inquiry | ||

Product Details

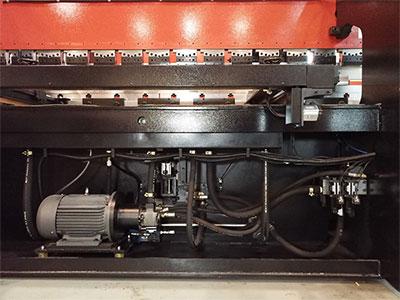

- The overall machine structure is a high-performance carbon steel with rust resistant paint, giving the press brakes a high strength and long service life.

- All major components have been subjected to stress relieving treatment.

- The slide stroke can be manually set for a single time.

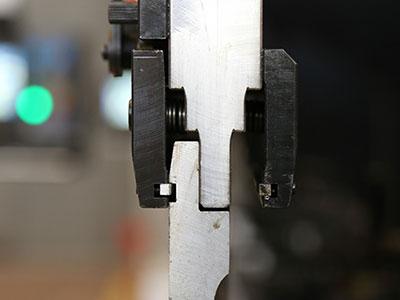

- With the use of a forced synchronization system, parallelism is maintained between the ram and the work table to effectively guarantee the bending accuracy.

- The hydraulic circuit is simple and easy to maintain.

- A rolling guide is used to keep the operation process flexible and decrease noise emissions.

- The servo driven back gauge finger is CNC controlled, ensuring the metal bending machine has a fast response and positioning.

- The CNC controller’s rotating arm ensures a flexible operation as it rotates freely in the operation area.

Operating Features

- Users can choose their language on the 10-inch LCD color touch screen.

- Data variable adjustments are completed via a manual handwheel or keyboard input.

- The calculation system is used to calculate the co-ordinates of the D axis, L axis, clamp point and bending angle.

- The computer is equipped with an online assistance system to guide operation, prompt faults, and guide simple maintenance.

- The back-gauge finger features a programmable retraction function to process complex units.

- Sound prompting and indicator light flashing activate when the sheet panel is positioned in place.

- The bottom time delay and clamping delay are set to ensure the bending process is smoother.

- Low speed bending technology is used to protect the workpiece bending surface and prevent accidents caused by the bending process.

Send an Inquiry