- Home

- Information

- How to Choose Press Brake Toolings

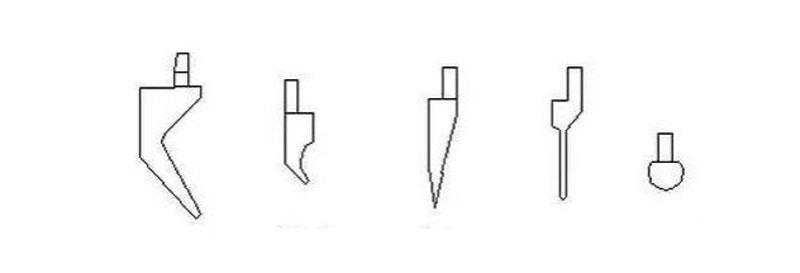

Workpieces are bent into different shapes using different press brake molds. The following are the main types:

Figure 1

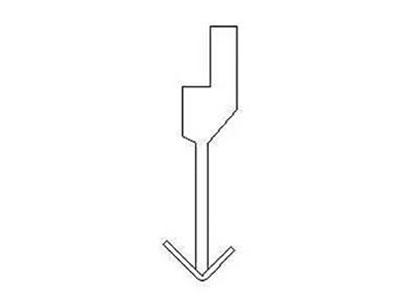

As shown in Figure 2, when a workpiece requires only one time bending and there is no need to take the bending position avoidance into consideration, a straight blade is preferred.

Figure 2

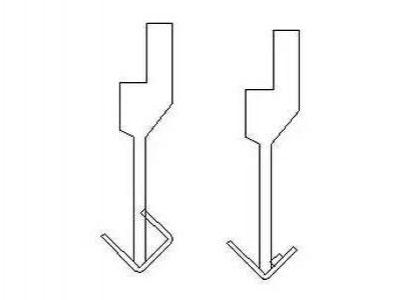

Bending position avoidance should be considered in the following situations, as shown in Figure 3.

Figure 3

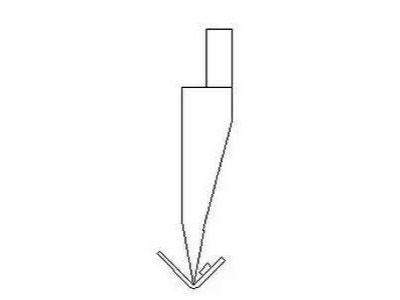

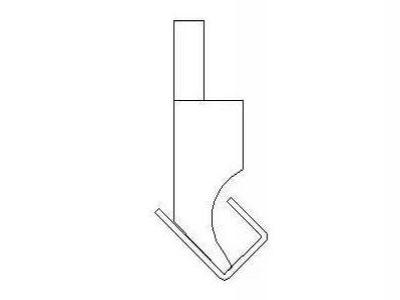

As shown above, there is an obvious interference in the bending process, so a different punch type should be considered for the bending process at this point, as shown in Figure 4 and Figure 5.

Figure 4

Figure 5

It should be noted that the punch head shown in Figure 5 is extremely sharp, so it cannot be used for bending thick metal plates. With the exception of the punch, dies are an important tool during the bending process.

Different problems can sometimes occur during bending processes, and customers need to carry out a specific analysis of the situation. AGN employs a professional team with extensive experience to offer the best advice according to your needs. Please do not hesitate to contact us.